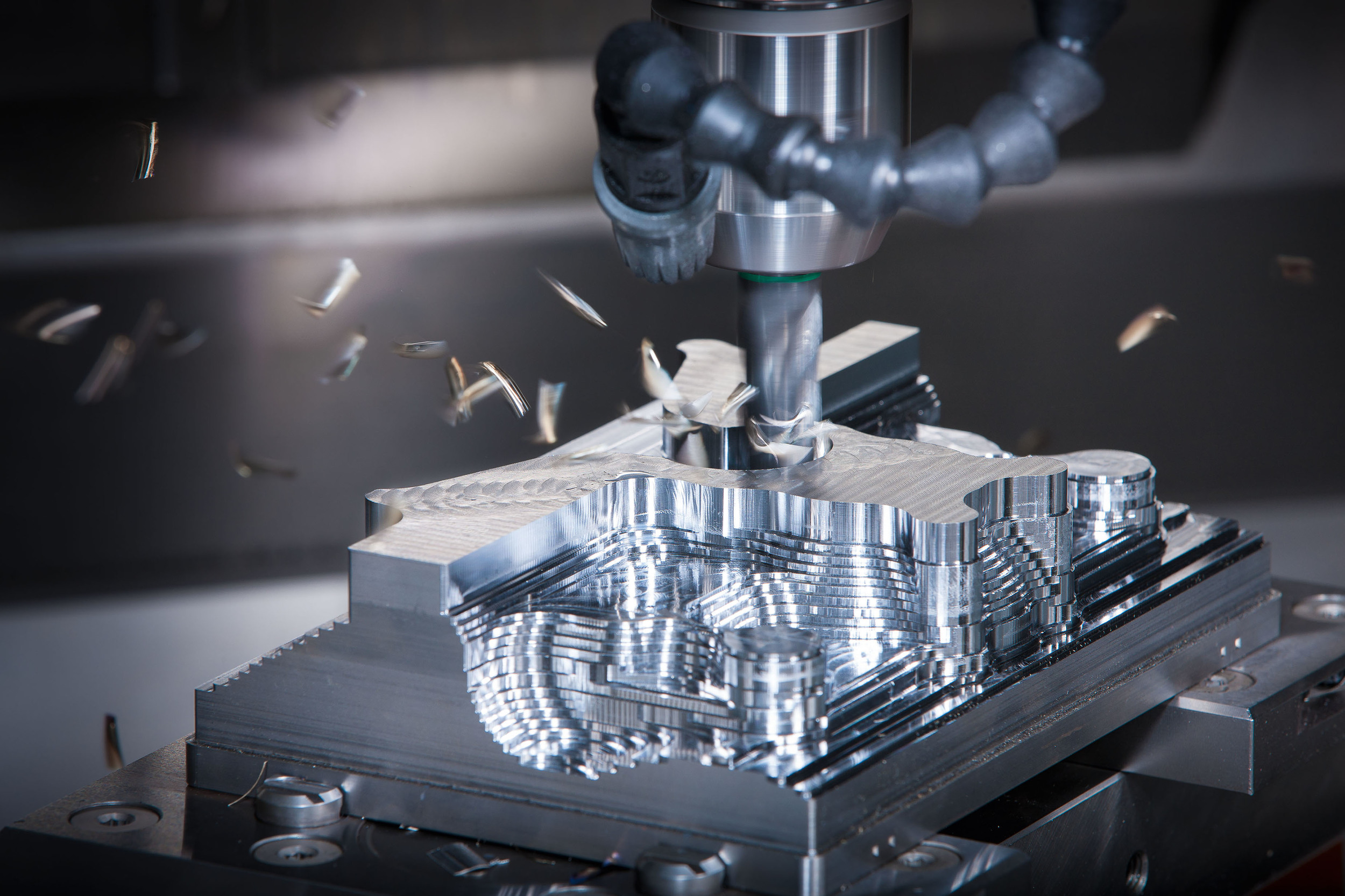

We've made our chips holding tolerances of

0.0002 inches and 0.005 mm.

ENGINEERING MACHINING REFURBISHING

- Full service engineering department

- Reverse engineering & inspection

- Access to 3D printing

- Design and build of special purpose machinery

- Design and build of dies, moulds, and gauges

- PLC programming & automation, including HMI

- CNC milling with 4th axis

- CNC turning with live tooling

- Wire EDM and hole popping

- Jig boring

- Jig grinding

- Cylindrical grinding

- Surface grinding

- Aida press for tryout services and small production runs

- Troubleshooting and refurbishing of existing high speed carbide dies

- Refurbishing of moulds, gauges, and high volume production machines that require very precise assembly tolerances

Additional Services

Over the past 55 years, we have expanded our network to include a large number of partnering suppliers who can handle parts that require:

- Heat treating

- 3D printing

- Flame cutting and welding

- Surface and blancher grinding of large plates

- Surface polishing

- Honing

- Centerless grinding

- Laser welding

- Engraving

- Chroming

- Nickel plating

- High performance coatings

- Gun drilling

- 5 axis machining

- Purchasing of solid carbide punches and dies for high speed stamping industry